How PLC Programming Is Handled by Control Systems Integrators

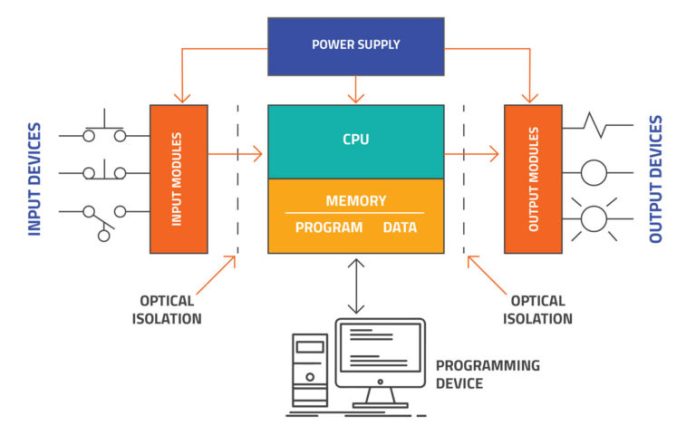

When it comes to industrial automation, PLC programming plays a central role in ensuring machines and processes work seamlessly together. But how exactly is this programming managed? The answer lies with control system integrators, the experts who design and implement systems that keep everything running smoothly. They handle the nitty-gritty of PLC programming, from developing complex logic to configuring communication protocols. Let’s dive into how these professionals tackle the various aspects of PLC programming.

Developing Ladder Logic for Streamlined Process Control

Ladder logic is the backbone of most PLC programming and has been used for decades due to its simplicity and effectiveness. Control system integrators often start by developing ladder logic to handle basic operations and control systems. The beauty of ladder logic is that it visually represents electrical circuits, making it easier to understand and modify.

For the controls integrator, ladder logic allows for streamlined process control. Whether it’s managing the sequence of operations in a manufacturing line or controlling motors and valves, ladder logic ensures processes flow smoothly. With clear, visual instructions, engineers can easily adjust parameters or troubleshoot the system without digging into complex code.

In larger systems, ladder logic becomes more sophisticated. Control system integrators often combine multiple ladder logic programs to create a cohesive control strategy. The advantage of this modular approach is that it simplifies maintenance and allows for easy updates or expansion in the future.

Configuring Communication Protocols for Device Integration

Beyond just writing code, control system integrators must ensure that PLCs can communicate effectively with various devices and systems. Configuring communication protocols is crucial for seamless control integration. These protocols determine how PLCs talk to sensors, motors, and even other PLCs.

The challenge is that not all devices speak the same language. A control system integrator needs to configure communication settings to ensure different devices can exchange data without errors. They may work with protocols like Modbus, EtherNet/IP, or Profibus, depending on the specific needs of the project. Getting the communication right ensures that data flows smoothly between devices, allowing the entire system to function without hiccups.

Moreover, this step also involves ensuring security within the communication network. A controls integrator has to consider not only how data is transferred but also how to protect it from interference or unauthorized access. Properly configured communication protocols enhance both the reliability and safety of the control system.

Implementing Structured Text for Complex Algorithms and Calculations

While ladder logic is great for simple control tasks, sometimes more complex operations require a different approach. That’s where structured text comes into play. This text-based language allows control system integrators to write more sophisticated algorithms and calculations that would be difficult to represent in a visual format like ladder logic.

Structured text is particularly useful when dealing with large data sets or when precise mathematical calculations are needed. A controls integrator might use structured text to calculate temperature control algorithms, monitor system efficiency, or manage advanced fault detection routines. The flexibility of this language allows for more dynamic and responsive control strategies.

One of the advantages of structured text is that it integrates seamlessly with other programming languages used in PLCs. Control system integrators can combine it with ladder logic or function block diagrams to create a robust and comprehensive program that handles everything from basic operations to complex decision-making processes.

Utilizing Function Block Diagrams for Modular Program Design

Function block diagrams (FBD) offer a more modular approach to PLC programming. These diagrams represent functions and logic blocks that can be reused and combined, making them an ideal choice for systems that require flexibility and scalability. Control system integrators often turn to FBDs when building modular systems that can be easily modified or expanded.

The modular design of function block diagrams is perfect for projects where individual components may need to be updated or replaced without overhauling the entire system. Controls integrators can create custom function blocks for specific tasks, allowing them to streamline programming and reduce errors. This approach ensures that even as the system evolves, the core logic remains consistent.

Additionally, function block diagrams provide a visual overview of the control process, which is especially helpful when multiple engineers are working on the same project. Each block is self-contained, making it easier for different team members to work on specific parts of the program without disrupting the entire system.

Testing and Debugging PLC Code to Ensure Operational Reliability

No PLC program is complete without thorough testing and debugging. Once the initial programming is done, control system integrators rigorously test the code to ensure it functions as expected. Testing involves running simulations to check how the PLC will respond in real-world scenarios, from normal operations to potential failure modes.

Debugging is often one of the more time-consuming aspects of PLC programming. A controls integrator must carefully analyze the program to identify and correct any issues that could cause malfunctions. This might involve stepping through the code line by line or using special debugging tools that monitor the PLC’s performance in real-time.

Thorough testing and debugging are critical for operational reliability. Even small errors in the code can lead to significant problems down the road. By testing every aspect of the program before deployment, control system integrators ensure that the system will operate smoothly once it’s up and running.

Adapting to Manufacturer-Specific Programming Environments and Standards

One of the more challenging aspects of PLC programming is adapting to the various programming environments provided by different manufacturers. Every brand has its own software, interface, and standards, and a control system integrator must be familiar with each to ensure compatibility with the equipment being used.

Different manufacturers may have proprietary programming environments. A skilled controls integrator needs to be proficient in these platforms, as each has its own nuances and specific requirements for developing effective PLC programs. This adaptability is key when working on projects involving equipment from multiple manufacturers.